टैबलेट बनाने की मशीन निर्माता

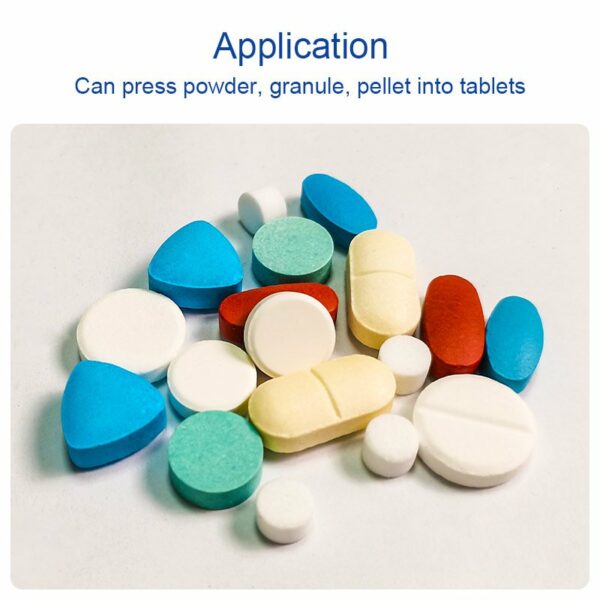

टैबलेट बनाने की मशीन निर्माता कार्य सिद्धांत में पाउडर को एक समान आकार और वजन की गोलियों में संपीड़ित करना शामिल है।

समायोज्य भरण गहराई: टैबलेट के वजन और आकार को नियंत्रित करने के लिए डाई की गहराई को समायोजित किया जा सकता है, जिससे प्रति टैबलेट सामग्री की सही खुराक सुनिश्चित होती है।

सतत संचालन: रोटरी टैबलेट प्रेस में, मशीन लगातार चलती रहती है, जिसमें कई डाई और पंच क्रम में घूमते रहते हैं, जिससे टैबलेट का उच्च गति से उत्पादन संभव होता है।

सारांश, टैबलेट प्रेस मशीन यह विधि डाई कैविटी में पाउडर के नियंत्रित संपीड़न का उपयोग करती है, जिससे गोलियाँ जल्दी और लगातार बनती हैं। यह विधि दवा, न्यूट्रास्युटिकल और रासायनिक उद्योगों में कुशल गोली उत्पादन के लिए व्यापक रूप से उपयोग की जाती है।

विशिष्टता:

110,000 टैब्स/घंटा तक

टैबलेट का अधिकतम व्यास 24 मिमी