In the pharmaceutical and nutraceutical industries, equipment procurement is never a simple transaction. For a buyer with more than 20 years of experience, every decision is guided by a balance of compliance, reliability, efficiency, and long-term value. Among all types of equipment, the blister packaging machine holds a unique position — it not only protects product integrity but also ensures patient safety, regulatory compliance, and production profitability.

So, what exactly does an experienced procurement professional look for when selecting a blister packaging machine? Below are the ten most important factors, organized by priority, along with the logic and insight that guide each decision.

1. Compliance and Certification

The very first question any experienced buyer asks is:

Does this equipment meet global pharmaceutical regulations such as cGMP, FDA, EMA, or NMPA standards?

And equally important: Can the manufacturer provide complete DQ/IQ/OQ/PQ validation documentation?

In the pharmaceutical industry, compliance is not optional — it’s the foundation of everything. A machine that fails to meet regulatory requirements cannot be installed in a cleanroom or used in production, no matter how advanced or affordable it seems. The lack of proper validation documents could result in rejected audits, product recalls, or even legal penalties.

2. Stability and Reliability

A blister packaging line that frequently breaks down can destroy production schedules and budgets.

That’s why experienced buyers focus on questions like:

What is the machine’s Mean Time Between Failures (MTBF)?

How stable is it during long, continuous production runs?

In the world of pharmaceuticals, downtime is the most expensive form of waste. A machine that stops unexpectedly not only delays delivery but also risks damaging valuable products and raw materials. As one veteran buyer puts it: “We would rather pay more for stability than save money on trouble.”

Reliable equipment translates to predictable output, fewer maintenance disruptions, and better control of overall manufacturing costs.

3. Technical Support and After-Sales Service

No matter how advanced a machine is, it will need maintenance.

An experienced procurement officer always evaluates a supplier’s service network, spare parts availability, and the technical expertise of its engineers. Quick, professional support minimizes production losses and protects the manufacturer’s reputation.

In industries where every hour of downtime matters, after-sales service quality directly determines the total lifecycle value of the machine.

4. Production Efficiency

In today’s competitive market, output equals competitiveness. Buyers closely examine a machine’s maximum stable running speed (cycles per minute) and the downtime required for product changeover.

A higher output capacity means that more products can be packed within the same shift, lowering the cost per unit. But efficiency isn’t only about speed — it’s about how easily the operator can switch formats, adjust settings, and keep the line running consistently.

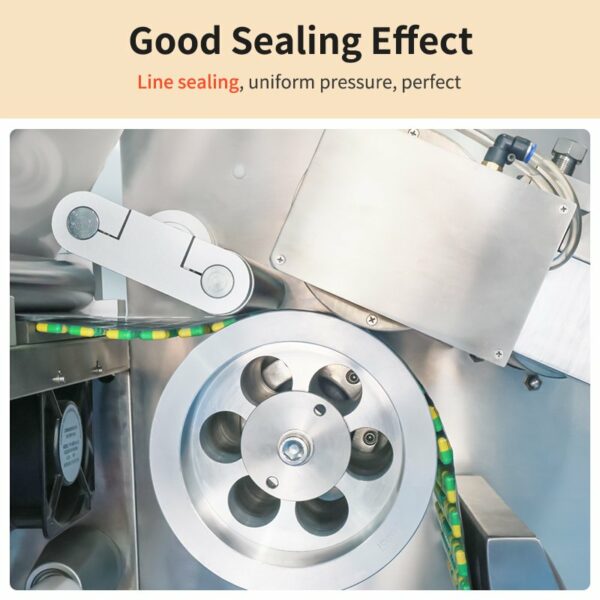

A modern blister machine should deliver high throughput without sacrificing sealing quality, alignment accuracy, or product integrity. That’s the balance every veteran buyer seeks.

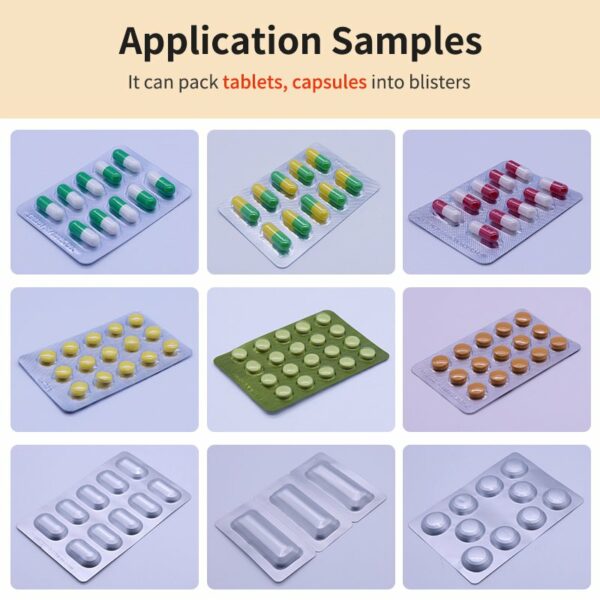

5. Material Compatibility and Flexibility

The pharmaceutical and nutraceutical industries are characterized by diverse packaging materials and product formats. An experienced buyer will always ask:

Can the machine handle PVC, PET, aluminum foil, or cold-form aluminum?

How easy is it to change molds and adjust parameters for different tablet sizes or capsule shapes?

Flexibility determines how well a packaging line can adapt to future products. For companies with various different tablets, capsules, soft gels — a flexible blister packing machine can save enormous time and cost when switching between production runs.

6. Ease of Cleaning and Maintenance

In pharmaceutical packaging, cleanliness is not just a matter of hygiene — it’s a regulatory requirement.

A practical question buyers ask is: Does the machine feature tool-free or quick cleaning?

Machines designed with easy cleaning in mind reduce cross-contamination risks and shorten batch changeover time.

A cleanable, low-maintenance design reflects the manufacturer’s understanding of cGMP and the realities of pharmaceutical production.

7. Technological Advancement and Smart Features

Modern automatic blister packaging machine are no longer purely mechanical. They are smart, data-driven systems equipped with automated inspection, defect detection, and data traceability functions.

Veteran buyers now look for features such as:

Automatic rejection of missing or broken tablets

Real-time monitoring of sealing quality

Connectivity with MES or ERP systems for batch tracking

User-friendly HMI with multilingual support

These intelligent functions not only ensure higher quality control but also align with the global shift toward Industry 4.0 manufacturing. A buyer with vision knows that smart automation today means regulatory compliance and competitive advantage tomorrow.

8. Spare Parts Supply

The reliability of a machine depends on the seller’s supply chain. Experienced buyers always pay attention to the following two points:

Can easily worn parts be purchased from a local hardware store, or must they be custom-made by the seller?

What are their lead times and prices?

Critical consumables such as heating plates, molds, or sealing gaskets should be easily obtainable. A long wait for parts can halt an entire production line. Therefore, suppliers with local spare parts warehouses and transparent pricing are far more attractive to procurement professionals.

9. Supplier Reputation and Proven Industry Cases

Finally, even the most impressive technical specifications mean little without real-world validation. Experienced buyers always ask:

Has this supplier successfully provided machines to reputable pharmaceutical or nutraceutical companies?

A supplier’s portfolio of successful case studies serves as living proof of reliability. Positive references and a strong reputation in the industry reduce procurement risk and provide confidence that the equipment will perform as promised.

A manufacturer with a history of supporting fortune 500 brands demonstrates not only technical capability but also long-term commitment.

10. Are the supporting products complete?

When you buy a blister packaging machine, you may also buy a cartoning machine, because you can’t directly present the blister packs to the consumers. If you can buy some upstream and downstream supporting equipment from one manufacture, it will save a lot of time and effort for professional procurement. For example, if you want to blister pack tablets, but you have a new project, capsule packing, this involves कैप्सूल भरने की मशीन, capsule counting bottling line cartoning machine etc.

निष्कर्ष

For seasoned professionals in pharmaceutical and nutraceutical procurement, the logic behind choosing a blister machine follows a clear hierarchy:

Compliance and safety come first — without them, nothing else matters.

Reliability, efficiency, and flexibility drive sustainable production.

After-sales service and total cost of ownership define long-term value.

Price, interestingly, often ranks last. In a highly regulated and quality-driven industry, the cheapest option is rarely the best. What truly matters is the assurance that every blister leaving the machine is safe, consistent, and compliant — because behind every package is a patient’s trust.

For manufacturer, understanding these priorities is the key to winning the confidence of professional buyers. It’s not just about selling a machine — it’s about delivering reliability, compliance, and partnership that last for decades.