टैबलेट काउंटिंग मशीन और कैप्सूल काउंटर सहित पिल काउंटर उपकरण, फार्मेसियों, चिकित्सा सुविधाओं और फार्मास्युटिकल उत्पादन इकाइयों में आवश्यक उपकरण बन गए हैं, जो दवाओं की गिनती की थकाऊ प्रक्रिया को काफी सरल बनाते हैं। एक उच्च-प्रदर्शन पिल काउंटर मशीन मैन्युअल त्रुटियों को कम करके और संचालन को गति देकर दक्षता बढ़ाती है। हालाँकि, ये स्वचालित टैबलेट काउंटर मशीनें सुविधाओं और मूल्य निर्धारण में व्यापक रूप से भिन्न होती हैं, जो स्वचालन स्तर, गिनती की गति और अतिरिक्त क्षमताओं जैसे कारकों से प्रभावित होती हैं। एक बुनियादी मैनुअल पिल काउंटर एक छोटी फार्मेसी के लिए पर्याप्त हो सकता है, जबकि उच्च-मात्रा संचालन के लिए आमतौर पर एक उन्नत स्वचालित गिनती मशीन की आवश्यकता होती है।

यह मूल्यांकन आपके खरीद निर्णय को निर्देशित करने के लिए महत्वपूर्ण विचारों पर प्रकाश डालता है। इसके अतिरिक्त, यह लेख विभिन्न पिल काउंटर मशीन मॉडल, उनकी मूल्य सीमा और एक आदर्श स्वचालित पिल काउंटर का चयन करने के लिए व्यावहारिक सुझावों की खोज करता है, जिससे बजट से अधिक खर्च किए बिना इष्टतम प्रदर्शन सुनिश्चित होता है।

1. गोली गिनने वाली मशीन चुनते समय ध्यान रखने योग्य आवश्यक विशेषताएं

गोली गिनने वाली मशीन में निवेश करने से फार्मेसियों, अस्पतालों और दवा निर्माण में दक्षता में उल्लेखनीय वृद्धि हो सकती है, लेकिन उचित स्वचालित गोली गिनने वाली मशीन का चयन करने के लिए सावधानीपूर्वक मूल्यांकन की आवश्यकता होती है। नीचे कुछ प्रमुख विशेषताएं दी गई हैं जिन्हें आपको निर्णय लेते समय प्राथमिकता देनी चाहिए:

स्वचालित गोली गिनने वाली मशीन

1.1 परिशुद्धता

स्वास्थ्य सेवा और दवा कंपनियों में, गिनती में मामूली गलतियों के भी गंभीर परिणाम हो सकते हैं। एक उन्नत गोली काउंटर मशीन सटीक गिनती सुनिश्चित करने के लिए उच्च परिशुद्धता फोटोइलेक्ट्रिक सेंसर, वजन-आधारित माप या एआई-सहायता प्राप्त विज़न सिस्टम का उपयोग करती है। एक स्वचालित गोली काउंटर मॉडल की तलाश करें जिसमें त्रुटि-पहचान तंत्र हो जो उपयोगकर्ताओं को उत्पाद विसंगतियों के बारे में सचेत करता है, जिससे गलत खुराक का जोखिम कम होता है।

1.2 गति और दक्षता

गोलियों और कैप्सूलों की गिनती की गति आपकी परिचालन आवश्यकताओं से मेल खानी चाहिए:

- किसी फार्मेसी के लिए, उसकी कम मात्रा में उत्पादन की आवश्यकता को पूरा करने के लिए अर्ध-स्वचालित टैबलेट काउंटिंग फिलिंग मशीन (प्रति मिनट 100-500 गोलियां गिनने और पैक करने वाली) से लाभ हो सकता है।

- अस्पतालों और दवा वितरकों जैसी उच्च-मात्रा वाली सुविधाओं को, कार्यप्रवाह दक्षता बनाए रखने के लिए, निरंतर फीडिंग तंत्र के साथ पूरी तरह से स्वचालित टैबलेट गिनने और भरने की मशीन प्रणालियों (प्रति मिनट 1,000 से अधिक गोलियों की गिनती और पैकेजिंग) की आवश्यकता होती है।

1.3 क्षमता और बहुमुखी प्रतिभा

इस बिंदु पर, आपको निम्नलिखित पर विचार करना होगा:

- फीडिंग हॉपर का आकार - क्या यह बार-बार गोलियां और कैप्सूल भरे बिना भारी मात्रा को संभाल सकता है?

- गोली अनुकूलता - क्या टैबलेट काउंटर कैप्सूल, टैबलेट और सॉफ्ट जेल सहित विभिन्न आकार, साइज और बनावट को समायोजित करता है?

- समायोज्य सेटिंग्स - क्या टैबलेट गिनती को विभिन्न आयामों की गोलियों और कैप्सूल की गिनती के लिए कैलिब्रेट किया जा सकता है?

1.4 स्थायित्व और रखरखाव

एक अच्छी तरह से निर्मित कैप्सूल काउंटर को स्टेनलेस स्टील या प्रबलित सामग्री से बनाया जाना चाहिए ताकि यह दैनिक उपयोग में टिक सके, घटकों के घिसने को कम करने के लिए इसमें न्यूनतम गतिशील भाग होने चाहिए, तथा स्वच्छता मानकों का पालन करने के लिए इसकी सतह को आसानी से साफ किया जा सके।

1.5 उपयोगकर्ता मित्रता

इलेक्ट्रॉनिक, सहज उपयोगकर्ता इंटरफ़ेस ऑपरेटर प्रशिक्षण में लागत और मैन्युअल हस्तक्षेप के कारण होने वाली त्रुटियों को कम करता है। मुख्य पहलुओं में स्पष्ट निर्देशों के साथ प्रत्यक्ष टचस्क्रीन नियंत्रण, विभिन्न प्रकार की गोलियों के लिए त्वरित-समायोजन तंत्र और निर्बाध संचालन के लिए न्यूनतम मैन्युअल हस्तक्षेप शामिल हैं।

1.6 लागत बनाम दीर्घकालिक मूल्य

जबकि बजट एक कारक है, अग्रिम कीमत पर स्वामित्व की कुल लागत को प्राथमिकता दें। कम रखरखाव आवृत्ति, उच्च गति और बेहतर सटीकता के साथ थोड़ा अधिक महंगा टैबलेट काउंटिंग मॉडल श्रम लागत को कम करके और त्रुटियों को समाप्त करके लंबे समय में पैसा बचा सकता है।

गोली गिनने वाली मशीन खरीदने से पहले, अपनी विशिष्ट गोली के प्रकारों के साथ विभिन्न मॉडलों का परीक्षण करें, बिक्री के बाद सहायता का आकलन करें और उपयोगकर्ता समीक्षाएँ पढ़ें। सबसे अच्छी गोली गिनने वाली मशीन गति, सटीकता, स्थायित्व और स्मार्ट सुविधाओं को संतुलित करती है, अनुपालन और लागत-दक्षता बनाए रखते हुए सुचारू संचालन सुनिश्चित करती है।

2. विभिन्न प्रकार के पिल काउंटर: आपके लिए सही फिट ढूँढना

2.1 मैनुअल पिल काउंटर

मैनुअल पिल काउंटर एक सरल उपकरण है जिसे छोटे पैमाने पर संचालन के लिए डिज़ाइन किया गया है। सस्ती और उपयोग में आसान, इन टैबलेट काउंटिंग मशीनों को बिजली या उन्नत तकनीक की आवश्यकता नहीं होती है। फ़ार्मेसी पिल काउंटर मशीन कम-आउटपुट फ़ार्मेसियों या बैकअप काउंटिंग विधि के लिए अच्छी तरह से काम करती है। हालाँकि, उनका धीमा संचालन उन्हें उच्च उत्पादन क्षमता की आवश्यकता वाली सेटिंग्स के लिए अव्यावहारिक बनाता है।

2.2 सेमी-ऑटो पिल काउंटर

एक सेमी ऑटो टैबलेट काउंटर मैन्युअल लोडिंग को स्वचालित टैबलेट कैप्सूल काउंटिंग के साथ जोड़ता है, एक सेमी-ऑटो पिल काउंटर मशीन मध्यम आकार की फ़ार्मेसियों के लिए उपयुक्त है। सेमी ऑटोमेटिक टैबलेट काउंटर मॉडल में पिल कलेक्शन ट्रे और बेसिक काउंटिंग मैकेनिज़्म जैसी सुविधाएँ शामिल हैं। जबकि सेमी-ऑटो पिल काउंटिंग मशीनें मैन्युअल विकल्पों की तुलना में तेज़ी से काम करती हैं, फिर भी उन्हें कुछ मानवीय भागीदारी की आवश्यकता होती है।

2.3 पूर्णतः स्वचालित गोली गिनने वाली मशीनें

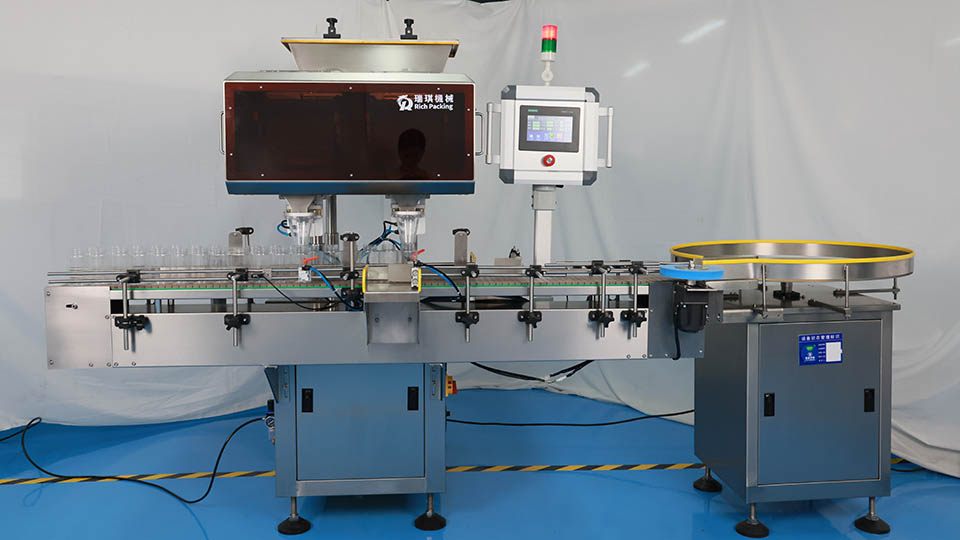

पूरी तरह से स्वचालित गोली गिनने वाली मशीन उच्च क्षमता वाली सुविधाओं के लिए एकदम सही समाधान है। पारंपरिक टैबलेट गिनने वाली मशीनों के विपरीत, ये उन्नत टैबलेट काउंटर सिस्टम फोटोइलेक्ट्रिक सेंसर तकनीक, स्व-अंशांकन और इन्वेंट्री ट्रैकिंग क्षमताओं को शामिल करते हैं, जो अधिक गति और सटीकता प्रदान करते हैं। उच्च दक्षता वाली स्वचालित गोली गिनने वाली मशीन विशेष रूप से बड़े पैमाने पर फ़ार्मेसियों, अस्पतालों और दवा निर्माताओं के लिए उपयोगी है जो एक साथ बड़ी मात्रा में नुस्खे प्रबंधित करते हैं।

आईएमए एक्टिव 500 और रुइडा पैकिंग आरडी डीएसएल 24बी दोनों ही शीर्ष स्तरीय टैबलेट गिनने वाली मशीनें हैं, जो असाधारण परिशुद्धता के साथ प्रति घंटे सैकड़ों हजारों गोलियां और कैप्सूल का प्रसंस्करण करने में सक्षम हैं।

लेना आरडी डीएसएल 24बी उदाहरण के लिए। यह स्वचालित गोली काउंटर ठोस खुराक रूपों की एक विस्तृत श्रृंखला को संभालने के लिए डिज़ाइन किया गया है, जिसमें टैबलेट और कैप्सूल (3-40 मिमी व्यास, पारदर्शी या अपारदर्शी हार्ड कैप्सूल, सॉफ्टजेल) शामिल हैं, जो दवा निर्माताओं, न्यूट्रास्युटिकल सप्लीमेंट उत्पादकों, अस्पतालों और अनुसंधान संस्थानों के लिए आदर्श है।

आइए इस स्वचालित गोली गिनने वाली मशीन की कुछ विशेषताओं पर एक नज़र डालें, जो एक आधुनिक गोली गिनने वाली मशीन की प्रमुख विशेषताएं भी हैं।

- उच्च सटीकतागिनती और भरने की सटीकता 99.7% से अधिक है, जो उद्योग मानकों को पार करती है।

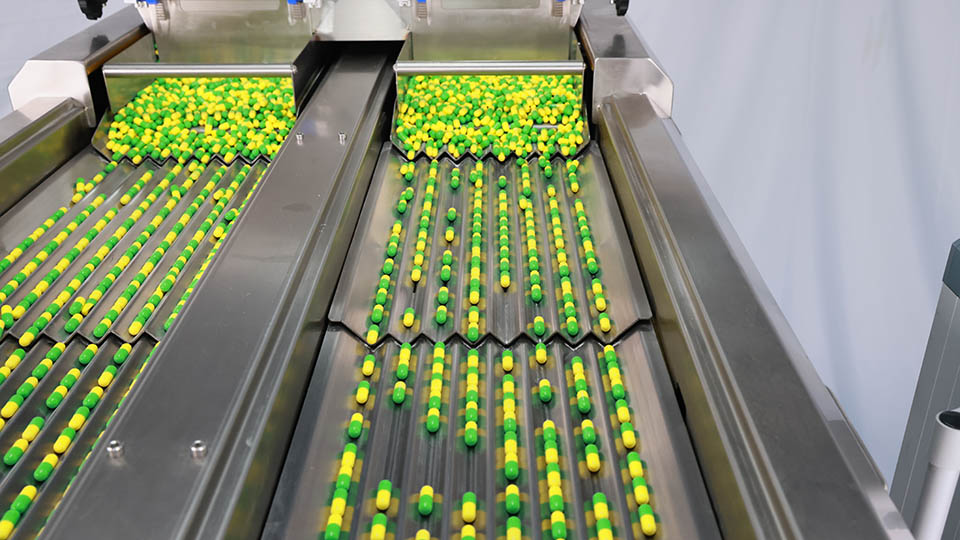

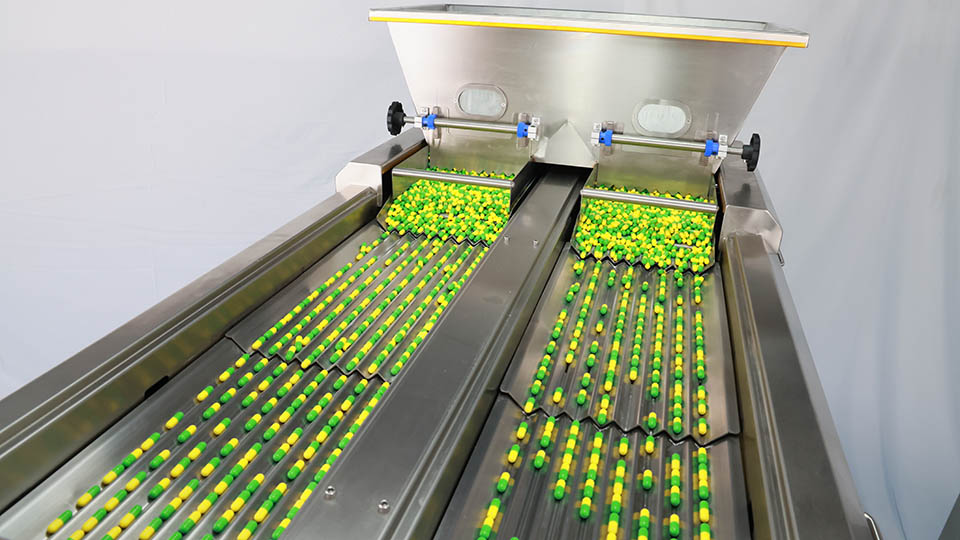

- बहु-चरण कंपन प्रौद्योगिकीबड़े, अनियमित या चिपचिपे कणों का सटीक पृथक्करण और गिनती करता है, जिससे गिनती चैनलों में टैबलेट और कैप्सूल का सुचारू प्रवाह सुनिश्चित होता है।

- बुद्धिमाननिगरानी प्रणालीयह स्वचालित गोली काउंटर को बोतल की स्थिति, सामग्री प्रवाह और परिचालन संबंधी दोषों का वास्तविक समय पर पता लगाने में सक्षम बनाता है, तथा त्रुटियों के लिए स्वतः रोक अलर्ट भी देता है।

- धूल-प्रतिरोधी इलेक्ट्रॉनिक्सटैबलेट गिनने वाली मशीन को उच्च धूल वाले वातावरण में भी विश्वसनीय प्रदर्शन बनाए रखने में मदद करें, जिससे निर्बाध उत्पादन सुनिश्चित हो सके।

- पूर्ण स्वचालन एकीकरणयह क्षमता स्वचालित गिनती मशीन को बोतल अनस्क्रैम्बलर्स, डेसीकैंट इंसर्टर्स, कैपिंग मशीनों, इंडक्शन सीलर्स और लेबलिंग मशीनों के साथ संगत बनाती है, जिससे एक पूर्ण स्वचालित पैकेजिंग लाइन बनती है।

कंपन कन्वेयर के तहत, गोलियों को गोली गिनने वाली मशीन के डिस्चार्ज पोर्ट के माध्यम से बोतलों में भरा जाता है।

IMA Active 500 और RD DSL 24B टैबलेट काउंटर मशीनें दोनों ही गति, सटीकता और स्वचालन प्रदान करती हैं, जो उन्हें उच्च-मात्रा उत्पादन के लिए आदर्श बनाती हैं। RD DSL 24B ऑटो पिल काउंटर मशीन चुनौतीपूर्ण सामग्रियों के लिए अपनी अनुकूलनशीलता और एंड-टू-एंड पैकेजिंग सिस्टम में सहज एकीकरण के लिए सबसे अलग है।

2.4 पोर्टेबल गोली काउंटर

कॉम्पैक्ट और हल्के, पोर्टेबल टैबलेट और कैप्सूल काउंटर आसान परिवहन प्रदान करते हैं, जो मोबाइल हेल्थकेयर इकाइयों, निजी प्रैक्टिस, पशु चिकित्सकों और क्लीनिकों के लिए एक आदर्श विकल्प बन जाता है। बल्क टैबलेट काउंटिंग मशीनों की क्षमता की कमी के बावजूद, उनकी सादगी और गतिशीलता छोटे पैमाने के संचालन के लिए महत्वपूर्ण लाभ हैं।

2.5 विशेष गोली काउंटर:

नाज़ुक कैप्सूल या अनियमित गोलियों की गिनती जैसे अनूठे अनुप्रयोगों के लिए डिज़ाइन की गई इस प्रकार की गोली काउंटर मशीन का व्यापक रूप से पशु चिकित्सा और दवा अनुसंधान प्रयोगशालाओं जैसी विशेष सेटिंग्स में उपयोग किया जाता है। इनमें से कई मशीनों में सटीक आवश्यकताओं को पूरा करने के लिए समायोज्य अंशांकन सहित अनुकूलन योग्य विकल्प हैं।

3. अपनी उत्पादन लाइन के लिए इष्टतम गोली गिनने वाली मशीन का चयन करना

सही गोली गिनने वाली मशीन चुनने के लिए आपकी सुविधा की विशिष्ट परिचालन मांगों का मूल्यांकन करना आवश्यक है। मुख्य बातों में शामिल हैं:

कैप्सूल गिनने वाली मशीन का मुख्य तंत्र

3.1 उत्पादन मात्रा मूल्यांकन

पैमाने से टैबलेट गिनने वाली मशीन का प्रकार तय होता है: उच्च-मात्रा वाली लाइनों को गति के लिए पूरी तरह से स्वचालित बल्क टैबलेट गिनने और भरने वाली मशीन की आवश्यकता होती है, जबकि छोटे ऑपरेशनों के लिए अर्ध-स्वचालित या पोर्टेबल इकाइयों की आवश्यकता होती है। एक पूरी तरह से स्वचालित टैबलेट काउंटर प्रति घंटे कम से कम 100,000 टैबलेट गिन सकता है, और एक उच्च-स्तरीय स्वचालित गिनने वाली मशीन अत्यधिक उच्च उत्पादन मात्रा को संतुष्ट कर सकती है। रुइडा पैकिंग का एक उन्नत टैबलेट काउंटर मॉडल प्रति घंटे 500,000 से अधिक दवा की गोलियां या कैप्सूल गिनता और पैक करता है।

3.2 चुनें इउपकरण सीके साथ संगत यहमारा एसविशिष्ट पीबीमार पीरोफ़ाइल्स

विविध टैबलेट रूपों और आयामों के लिए अलग-अलग दक्षता और सटीकता के साथ अलग-अलग गिनती समाधान की आवश्यकता होती है। अपनी उत्पादन लाइन के लिए मशीनरी प्राप्त करते समय, अपनी सुविधा की परिचालन आवश्यकताओं को पूरा करने के लिए अपनी टैबलेट काउंटिंग फिलिंग मशीन की क्षमता को सत्यापित करें, विशेष रूप से अनियमित आकार की दवा की गोलियाँ या शारीरिक क्षति के लिए अतिसंवेदनशील नाजुक कैप्सूल। ऐसे विशेष गोली रूपों के लिए समर्पित गोली काउंटर की आवश्यकता हो सकती है।

3.3 परिशुद्धता और थ्रूपुट

गिनती की त्रुटियों को दूर करने के लिए उच्च-सटीकता वाले सेंसर को प्राथमिकता दें। समय-संवेदनशील कार्यों के लिए, तेजी से वितरण करने वाले मॉडल (हजारों/मिनट) चुनें। कई पूरी तरह से स्वचालित गोली गिनने वाली मशीनों में असाधारण गिनती सटीकता प्रदान करने के लिए उच्च-सटीकता वाले फोटोइलेक्ट्रिक गिनती सेंसर या यहां तक कि वास्तविक समय दृष्टि प्रणाली भी होती है।

3.4 एकीकरण क्षमताएँ

बड़ी विनिर्माण सुविधाओं को इन्वेंट्री प्रबंधन, स्वचालित रिपोर्टिंग और त्रुटि-पहचान सुविधाओं की तलाश करनी चाहिए। छोटे सेटअप के लिए सरल मॉडल पर्याप्त हैं।

3.5 लागत विश्लेषण

प्रारंभिक निवेश को दीर्घकालिक कारकों के विरुद्ध संतुलित करें: उपकरण स्थायित्व, मशीन रखरखाव सुविधा, श्रम बचत और मापनीयता। उच्च प्रदर्शन करने वाला टैबलेट काउंटिंग मॉडल अक्सर समय के साथ अधिक ROI देता है।

4. इष्टतम सटीकता और दीर्घायु के लिए अपनी गोली गिनने वाली मशीन का रखरखाव कैसे करें

विभिन्न विकल्पों में से एक उचित और आदर्श कैप्सूल टैबलेट गिनने वाली मशीन का चयन सफल गोली गिनती और पैकेजिंग की नींव रखता है, जबकि नियमित रखरखाव प्रक्रियाओं का पालन करने से आपकी टैबलेट कैप्सूल गिनने वाली मशीन का प्रदर्शन लंबा और स्थिर हो जाता है।

4.1 नियमित सफाई की महत्वपूर्ण भूमिका

स्वचालित गोली काउंटर के इस्तेमाल के बाद भी सफ़ाई की आवृत्ति बनाए रखें। हर शिफ्ट या उत्पादन बैच बदलने के बाद सफ़ाई करें, और हर हफ़्ते गहरी सफ़ाई करें।

गिनती मशीन के घटकों को अलग करना

सफ़ाई से पहले, गोली के संपर्क में आने वाले घटकों को व्यवस्थित रूप से हटा दें। दवा की गोलियों के संपर्क में आने वाले भागों में शामिल हैं:

- गोली कैप्सूल खिलाने वाला हॉपर: सबसे पहले इस उपकरण को अलग कर लें क्योंकि पाउडर और दाना अवशेष अक्सर हॉपर की दीवारों से चिपक जाते हैं।

- कंपन वाहक: गोलियों और कैप्सूलों को हॉपर से टैबलेट काउंटिंग चैनल तक पहुंचाने वाले वाहक को अनलॉक करें, तथा गलत संरेखण से बचने के लिए उन्हें धीरे से हटाएं।

- टैबलेट गिनती चैनल: गैर-घर्षण उपकरणों के साथ रुकावट पैदा करने वाली किसी भी सामग्री को साफ़ करें।

- डिस्चार्ज पोर्ट: किसी भी फंसी हुई गोली या मलबे की जांच करें।

4.2 सफाई पद्धति

- अल्ट्रासोनिक बाथ: अल्ट्रासोनिक बाथ उच्च आवृत्ति की ध्वनि तरंगों का उपयोग करके सफाई समाधान का छिड़काव करता है। हॉपर, टैबलेट काउंटिंग चैनल, डिस्चार्ज च्यूट और कन्वेइंग ट्रे में अक्सर जटिल आकार, खांचे और पहुंचने में मुश्किल क्षेत्र होते हैं जहां पाउडर अवशेष जमा हो सकते हैं। अल्ट्रासोनिक बाथ इन क्षेत्रों में कहीं अधिक प्रभावी ढंग से प्रवेश करता है।

- मुलायम ब्रश और लिंट-फ्री कपड़े: घटकों को हटाने के बाद, सभी सतहों से पाउडर अवशेषों को सख्ती से साफ़ करने के लिए मुलायम ब्रश का उपयोग करें। इसके बाद, गैर-इलेक्ट्रॉनिक सतहों को पोंछने के लिए थोड़ा गीला लिंट-फ्री कपड़े (70% IPA जैसे निर्माता द्वारा अनुमोदित क्लीनर या यदि आवश्यक हो तो पानी के साथ) का उपयोग करें।

- सुखाना: टैबलेट गिनने की मशीन को साफ करने के बाद पूरी तरह से सुखा लें, ताकि यह सुनिश्चित हो सके कि सभी भाग और सतहें पूरी तरह से सूख गई हैं। पुनः संयोजन से पहले हवा से सुखाएं या साफ, सूखे लिंट-फ्री कपड़े का उपयोग करें।

4.3 निर्माता द्वारा अनुशंसित समाधान: अनिवार्य

जेनेरिक क्लीनर सतहों को खराब कर सकते हैं या विषाक्त अवशेष छोड़ सकते हैं। हमेशा अपने उपयोगकर्ता मैनुअल में निर्दिष्ट समाधान, आम तौर पर पीएच-तटस्थ और गैर-फोमिंग एजेंट का उपयोग करें। कार्बनिक अवशेषों के लिए, एंजाइमेटिक क्लीनर की सलाह दी जा सकती है।

4.4 नाज़ुक चीज़ों को संभालना: “पानी न डालें” नियम

महत्वपूर्ण इलेक्ट्रॉनिक्स और वायवीय रूप से संचालित भागों को विशेष देखभाल की आवश्यकता होती है।

जब वाल्व प्लेट और न्यूमेटिक सिलेंडर की बात आती है, तो बाहरी हिस्से को सूखे इलेक्ट्रोस्टैटिक कपड़े से पोंछें। ऑप्टिकल सेंसर को साफ करते समय, जिसे फोटोइलेक्ट्रिक काउंटिंग सेंसर भी कहा जाता है, लेंस को ऑप्टिकल-ग्रेड वाइप्स और सेंसर-सेफ अल्कोहल से साफ करें। बोतल डिटेक्शन सेंसर को स्वच्छ रखने के मामले में, मलबे को धीरे से ब्रश से हटाएं और तरल पदार्थ के संपर्क से बचें।

4.5 भंडारण और परिचालन संबंधी सर्वोत्तम अभ्यास

टैबलेट गिनने और भरने की मशीन को जलवायु-नियंत्रित कमरे में रखें, जहाँ आर्द्रता <60% और तापमान 15–25°C हो। धूल-रोधी कवर ज़रूरी हैं।

इसके अतिरिक्त, दुरुपयोग की रोकथाम पर ध्यान दें। टैबलेट और कैप्सूल की गिनती और भरने की क्षमता को कभी भी मशीन की अधिकतम गोली हैंडलिंग क्षमता से अधिक न होने दें। विशेष कोटिंग के बिना हाइग्रोस्कोपिक या चिपचिपी टैबलेट की गिनती से बचें। एक और महत्वपूर्ण बिंदु यह है कि सुरक्षा और पहनने को कम करने के विचारों के लिए सफाई के दौरान या जब यह निष्क्रिय हो तो हमेशा कैप्सूल टैबलेट काउंटर को बंद रखें।

अंतिम शब्द

उच्च गुणवत्ता वाले टैबलेट काउंटर में निवेश करने से परिचालन प्रवाह और दक्षता में वृद्धि होती है, जबकि रोगियों को सीधे लाभ होता है। फ़ार्मेसी स्वचालन गलत गणना और त्रुटियों को कम करके प्रिस्क्रिप्शन की सटीकता सुनिश्चित करता है, जिससे रोगियों को लगातार, सही दवा प्राप्त होती है। इसके अलावा, टैबलेट गिनने की प्रक्रिया को स्वचालित करने से फार्मासिस्ट और तकनीशियनों को मैन्युअल गोली गिनने के बजाय रोगी परामर्श और इन्वेंट्री प्रबंधन जैसी उच्च-मूल्य वाली ज़िम्मेदारियों पर अपना ध्यान केंद्रित करने की अनुमति मिलती है।