ট্যাবলেট এবং ক্যাপসুল কাউন্টিং ফিলিং মেশিন

ট্যাবলেট এবং ক্যাপসুল কাউন্টিং ফিলিং মেশিন সঠিক গণনা এবং পাত্রে দক্ষ ভরাট নিশ্চিত করার জন্য ডিজাইন করা বেশ কয়েকটি সুনির্দিষ্ট পদক্ষেপ জড়িত।

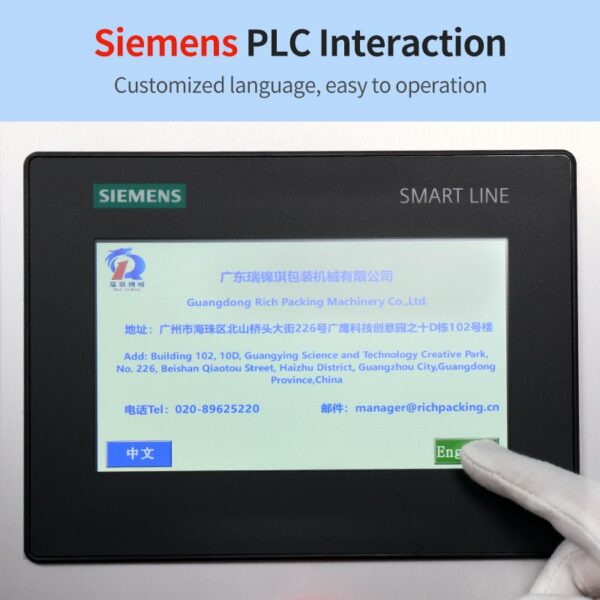

অপটিক্যাল সেন্সর: মেশিনটি উন্নত অপটিক্যাল সেন্সর (যেমন, ইনফ্রারেড বা এলইডি সেন্সর) ব্যবহার করে ট্যাবলেট বা ক্যাপসুলগুলি যখন কোনও চুট বা চ্যানেলের মধ্য দিয়ে যায় তখন তা সনাক্ত এবং গণনা করে।

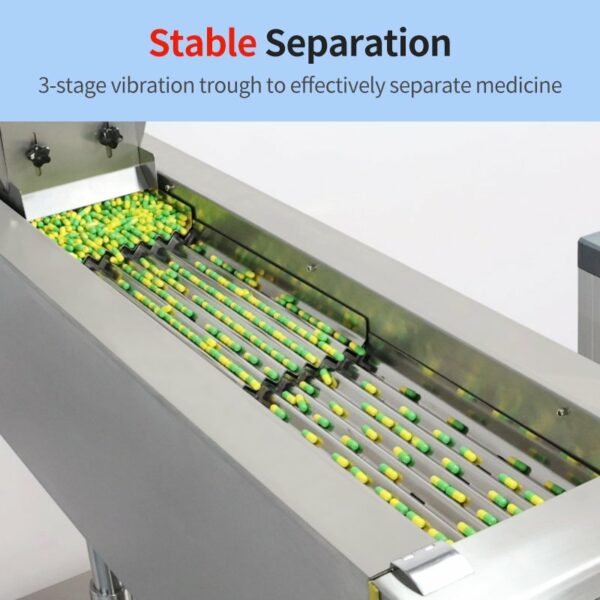

মাল্টিচ্যানেল ডিজাইন: অনেক মেশিনে একাধিক চ্যানেল বা ট্র্যাক থাকে যা একসাথে একাধিক পণ্য গণনা করে, যা থ্রুপুট বৃদ্ধি করে।

প্রত্যাখ্যান প্রক্রিয়া: যদি কোনও বিদেশী বস্তু বা ত্রুটিপূর্ণ জিনিস সনাক্ত করা হয়, তবে সেগুলিকে ভরাট প্রক্রিয়া থেকে দূরে সরিয়ে দেওয়া হয়।

ভর্তি প্রক্রিয়া: গণনা করা ট্যাবলেট বা ক্যাপসুলগুলিকে নোজেলের মধ্যে পাত্রে (বোতল, জার, ইত্যাদি) পাঠানো হয়। একটি সময় ব্যবস্থা নিশ্চিত করে যে প্রতিটি পাত্রে সঠিক সংখ্যক পণ্য বিতরণ করা হয়েছে।

এই প্রক্রিয়াটি ফার্মাসিউটিক্যাল এবং নিউট্রাসিউটিক্যাল পণ্যের জন্য সঠিক এবং উচ্চ-গতির ফিলিং নিশ্চিত করে এবং কঠোর শিল্প মান পূরণ করে।

স্পেসিফিকেশন:

৫০ বোতল/মিনিট পর্যন্ত

৭ দিনের দ্রুত ডেলিভারি

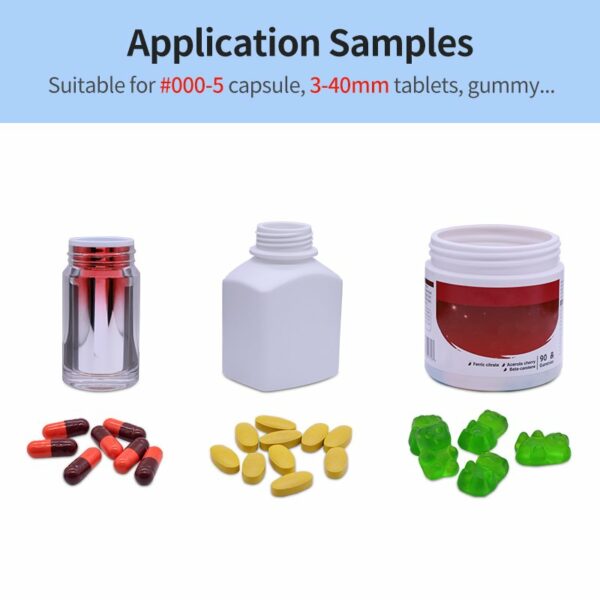

৩-৪০ মিমি ক্যাপসুল/ট্যাবলেট/গামির জন্য উপযুক্ত...